Engineering mistakes that changed history reveal how miscalculations, overlooked details, or flawed assumptions can alter the course of nations, economies, and human lives. These events offer powerful lessons about precision, accountability, innovation, risk analysis, and real-world consequences. While engineering is built on planning, testing, and validation, even small errors can create massive ripple effects felt for decades.

When Design Flaws Meet Real-World Pressure

Some engineering failures resulted from untested assumptions. Others happened because the final structure or system faced unexpected environmental forces, fatigue, or human misuse. Engineering is not just about designing what works, but designing what will continue to work under worst-case scenarios.

Common Factors Behind Historical Engineering Failure

- Insufficient testing or simulation

- Design assumptions that ignored real-world conditions

- Poor material choice or quality control

- Communication failures between departments

- Miscalculations and overlooked load capacity

- Pressure to reduce cost or shorten project schedules

- Human error and leadership decisions overriding experts

Understanding why failures happened helps prevent repetition, evolve engineering standards, and build safer infrastructures.

The Mars Climate Orbiter Metric Miscalculation

In 1999, NASA lost the Mars Climate Orbiter because one engineering team used metric units while another used imperial units. The spacecraft entered Mars’ atmosphere at the wrong trajectory and disintegrated.

Key Impact

- Loss of a 125 million dollar spacecraft

- Renewed focus on inter-team communication and unit verification

- Standardization of measurement systems in aerospace projects

This incident remains one of the most referenced examples in aerospace engineering education because it shows how a simple conversion error can destroy years of research.

Tacoma Narrows Bridge Collapse

The Tacoma Narrows Bridge in Washington opened in 1940 and collapsed just four months later due to aeroelastic flutter. Engineers underestimated wind-induced oscillations, creating one of the most dramatic and documented bridge failures in history.

What Went Wrong

- Narrow and lightweight deck amplified vibrations

- Lack of adequate stiffness and aerodynamic testing

- Failure to incorporate wind tunnel modeling used in earlier major bridges

Long-Term Consequences

- Wind engineering became a critical field

- Revised global standards for suspension bridge aerodynamics

- Structural damping and aerodynamic girder designs became mandatory

Chernobyl Reactor Disaster

The Chernobyl nuclear power plant disaster in 1986 remains one of the most devastating engineering and safety failures recorded. The reactor’s flawed design combined with improper test procedures resulted in an explosion that released radioactive material across Europe.

Contributing Engineering Issues

- Graphite-tipped control rods that increased reactivity at insertion

- Reactor instability at low power levels

- Incomplete understanding of fail-safe mechanisms among operators

Global Outcomes

- Major advancements in nuclear safety engineering

- Creation of international nuclear monitoring organizations

- Reinforced importance of safety-over-production policies

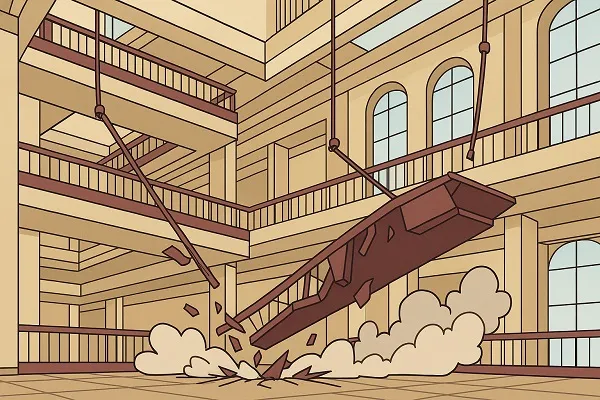

Hyatt Regency Walkway Collapse

In 1981, two suspended walkways inside the Kansas City Hyatt Regency hotel collapsed, killing over 100 people. The disaster was traced to a design change that doubled the load on connection rods without re-calculating structural stresses.

Lessons Learned

- Every modification must undergo full engineering verification

- Fast-tracking construction increases risk

- Redundancy and load-path clarity are essential for public structures

This tragedy reshaped architectural and structural review procedures across the United States.

The Challenger Space Shuttle Explosion

The Space Shuttle Challenger exploded 73 seconds after launch in 1986 due to O-ring seal failure caused by low temperatures. Engineers had raised safety concerns, but launch proceeded under external pressure and tight scheduling expectations.

Critical Factors

- Misjudgment of material performance in cold weather

- Suppression of expert warnings during executive decision-making

- Risk prioritization influenced by non-technical goals

The Challenger disaster emphasized that engineering safety cannot be compromised for political or schedule-driven agendas.

Millennium Bridge Swaying Instability

London’s Millennium Bridge opened in June 2000 but was closed two days later due to unexpected lateral swaying. Thousands of pedestrians walking in synchrony caused resonance forces that exceeded damping capacity.

Engineering Takeaways

- Human movement can act as coordinated dynamic loading

- Mathematical modeling must consider crowd behavior

- Retrofitting with dampers restored stability without demolishing the structure

This incident reshaped pedestrian bridge design analysis strategies worldwide.

The Ford Pinto Fuel Tank Defect

The Ford Pinto, produced in the 1970s, earned notoriety for a fuel-tank placement flaw that could lead to explosions in rear-end collisions. Engineering trade-offs to meet weight and cost targets overshadowed safety considerations.

Core Issues

- Inadequate crash testing at design stage

- Safety recommendations deprioritized to meet release timeline

- Legal and reputational damage exceeded cost-saving goals

This case influenced automotive safety regulations and ethical engineering decision-making.

St. Francis Dam Failure

In 1928, the St. Francis Dam near Los Angeles collapsed, causing one of the worst civil engineering disasters in US history. Geological conditions beneath the dam were misjudged and unexamined, leading to catastrophic failure.

Resulting Changes

- Mandatory geological surveys for major construction

- Formation of dam safety regulatory agencies

- Enhanced hydro-engineering research and oversight

Engineering Errors Still Shape Safety Standards

Engineering mistakes that changed history serve as real-world reminders of how critical testing, collaboration, and risk assessment truly are. These events reshaped safety codes, testing methods, material standards, and ethical responsibility throughout engineering disciplines.

Key Principles Strengthened by Historical Failures

- Always validate assumptions through testing

- Use conservative design margins for unknown variables

- Encourage transparent communication surrounding risks

- Document every design change with load and safety recalculations

- Recognize that engineering decisions affect lives, not just numbers

Real-world engineering failures are powerful case studies that sharpen engineering education, influence modern design codes, and reinforce accountability across industries. The legacy of these events is not merely tragedy, but progress, innovation, and improved global safety culture.

Content reviewed and published by Tier2Tek Staffing Editorial Team .