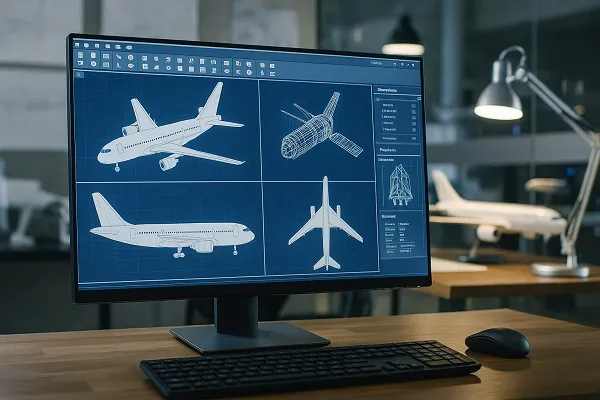

Computer-Aided Design (CAD) in aerospace engineering has transformed how aircraft, spacecraft, and related systems are designed and manufactured. From conceptualization to testing, CAD enables engineers to create highly precise models, run simulations, and optimize every detail for performance and safety in the skies.

The Evolution of CAD in Aerospace

The aerospace industry has been a pioneer in adopting CAD technologies since the 1960s. Early on, it was used primarily for drafting, but as software advanced, CAD became integral to the entire product lifecycle.

Milestones in Aerospace CAD:

- 1960s-70s: Introduction of 2D CAD systems for basic drafting.

- 1980s: Emergence of 3D modeling, allowing for more complex geometry.

- 1990s: Integration with CAM (Computer-Aided Manufacturing) and CAE (Computer-Aided Engineering).

- 2000s-Present: Advanced simulations, digital twins, and collaborative cloud-based design.

Core Benefits of CAD in Aerospace Design

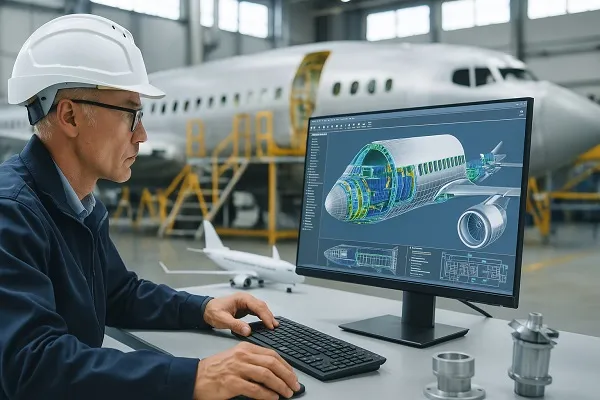

CAD is vital in helping engineers meet the demanding requirements of the aerospace sector.

Precision and Complexity

Aerospace components often involve intricate geometries and tight tolerances. CAD tools enable the creation of accurate 3D models that reflect real-world specifications.

Time and Cost Efficiency

CAD reduces the need for physical prototypes. Virtual testing and iterative design cut down both development time and costs significantly.

Collaboration and Integration

Modern CAD software supports collaboration among international teams and integrates seamlessly with PLM (Product Lifecycle Management) systems.

Key Applications of CAD in Aerospace

Aircraft Structural Design

- Wing and fuselage design

- Load-bearing structural analysis

- Material optimization for weight reduction

Avionics and Systems Integration

CAD supports the layout and integration of complex avionics systems, ensuring spatial efficiency and compliance with safety regulations.

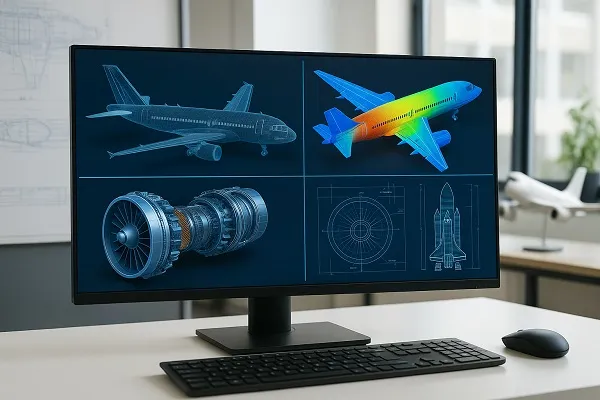

Aerodynamics and CFD Simulation

Many CAD platforms are coupled with CFD (Computational Fluid Dynamics) tools to simulate airflow over surfaces. This helps refine aerodynamic properties before any physical model is built.

Spacecraft and Satellite Development

- Orbital mechanics modeling

- Component configuration for extreme environments

- Integration of propulsion and communication systems

Popular CAD Tools in Aerospace Engineering

Here are some of the most widely used CAD platforms in the aerospace industry:

- CATIA: Preferred for complex assemblies and systems engineering (used by Airbus and Boeing).

- Siemens NX: Offers advanced simulation and digital twin capabilities.

- Autodesk Fusion 360: Gaining popularity for lightweight, integrated workflows.

- SolidWorks: Used for smaller aerospace suppliers and prototyping.

Digital Twins and Virtual Testing

A groundbreaking advancement is the use of digital twins—virtual replicas of physical systems.

- They allow for real-time monitoring and simulation.

- Engineers can predict system failures or maintenance needs.

- Performance can be evaluated across various flight conditions without physical trials.

CAD in Aerospace Manufacturing

Once the design is complete, CAD models are directly used in the manufacturing process.

CAD to CAM Workflow:

- Direct conversion of 3D models to machining instructions.

- Minimizes manual errors.

- Accelerates production cycles.

Additive Manufacturing Integration

With the rise of 3D printing in aerospace, CAD models now directly inform layer-by-layer fabrication. This is especially useful for lightweight components and custom parts.

Challenges and Considerations

Despite its advantages, CAD in aerospace comes with specific challenges:

- High Learning Curve: Advanced features require significant training.

- Data Security: Aerospace designs are often classified or sensitive.

- Software Compatibility: Integrating different CAD tools across suppliers can lead to inconsistencies.

The Future of CAD in Aerospace

CAD is increasingly integrating with AI and machine learning to offer predictive design capabilities. The future points to more automation, real-time collaboration, and sustainability-focused features in aerospace CAD workflows.

Emerging trends:

- AI-driven optimization for fuel efficiency

- Generative design for unique structural forms

- Cloud-based design hubs for global collaboration

Why CAD Is Indispensable to Modern Aerospace

In an industry where failure is not an option, CAD tools offer the precision, efficiency, and flexibility needed to innovate and meet stringent safety and performance standards. As aerospace design becomes more complex, the role of CAD will only grow more critical.

References

- NASA – Digital Engineering Strategy

- Federal Aviation Administration – Aircraft Certification

- MIT OpenCourseWare – Aerospace Design

Content reviewed and published by Tier2Tek Staffing Editorial Team .